We manufacture based on the customer’s needs; from a one-piece sample prototype and finished product to a production run exceeding one million pieces. Thorndike Corporation’s finished products include thousands of components in a variety of shapes and sizes that were developed and produced to meet customer’s needs. Our methods and the special array of tools, dies, forms and jigs we have created have made us unique in the industry and have made it possible for us to economically mass produce parts. For new designs, prototypes, or engineering upgrades, we provide the electrical and mechanical design for many types of microwave products, from system specifications.

What Thorndike Corporation offers the Customer:

What Thorndike Corporation offers the Customer:

Full machine shop with C.N.C lathes, C.N.C millers, lathes, millers, surface grinding, Blanchard grinding & Centerless grinding. Mold, machine, die cut and grind raw stock materials. Capabilities include but are not limited to

- Copper & Brass

- Titanium

- Aluminum

- Stainless steel

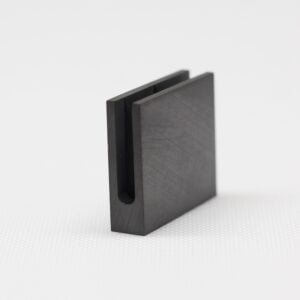

- Ferrites

- Garnets

- Magnets

- Silicon Carbide (all grades including refractory – MANUFACTURED IN HOUSE)

- Ceramics

- Flexible Absorber materials (typically 2 GHz and above – MANUFACTURED IN HOUSE)

- Polyiron materials (typically 2 GHz and above – MANUFACTURED IN HOUSE)

- Alumina

- Ferrous and non-ferrous materials

- Boron Nitride

- Plastics

- Thorndike Corporation is a one stop machine shop from design, engineering, assembly to shipping. We now feature a new microwave termination line (low power, Double ridge waveguide, medium power & High Power). Please contact us for additional information.

- Engineer prototypes or full production runs

- Stock items ship within 24 hours and lead time for custom orders is per customer request

- We provide the optimum shapes, materials and design for high power applications, low cost, special frequency and wide band applications.

If you have a unique need, provide the WR size, frequency, VSWR, max length, power desired and any mounting requirements. We can match your specifications with one from our vast, still expanding line of Thorndike products (exceeding 37,000) which we have developed over the past 80 years or design and produce a brand-new product meeting customer specifications.

What Our Customers Say

Typical High and Low Power Thorndike Products

- Cone Terminations (High & Low Power), Thorndike Series CLXXXX™ & CLXXXX-HPC™

- Step & Tongue Loads (High & Low Power), Thorndike Series TLXXXX™ & TLXXXX-HPC™

- Wedge Loads (High & Low Power), Thorndike Series WLXXXX™ & WLXXXX-HPC™

- Double Tapered Spear Load (High & Low Power), Thorndike Series DTWXXXX™

- Channel Loads (High Power), Thorndike Series CHLXXXX™

- Ridgeguide Loads (High & Low Power), Thorndike Series RSLXXXX™

- Taper Spear Loads (High Power), Thorndike Series THPXXXX™

- Dual Angles Tapered Spear Loads (High Power), Thorndike Series DTHPXXXX™

- Filler Cavity Backs

- Choke Rings & Bearings

- Dampening Rings

- Attenuator Bushings

- Rotary Joint Bushings

- Attenuators

- Coax Variable Attenuators

What Thorndike Corporation offers the Customer:

What Thorndike Corporation offers the Customer: